More than anywhere else, ventilation and air conditioning systems in hospitals and other highly sensitive areas of health care, need to meet critical hygiene and safety requirements. Since every component in the HVAC system needs to comply to these stringent requirements, Rf-Technologies has a range of tested and certified fire dampers carrying a ‘Hygiene Tested’ label.

All Rf-t products are safe and hygienic by design, independent from the area of application. But for some environments, we need to meet increased hygienic requirements. In hospitals, and particularly in operating rooms, intensive care units, maternity or neonatal units, cleanrooms and labs, room air contamination must be avoided at all times. Dust, airborne bacterial contaminants, waste anaesthetic gases and odorous substances need to be contained, kept to a minimum level and removed by an effective and reliable air conditioning system.

But also any other environment where airborne particles can have serious consequences or affect the quality of the manufactured products, such as pharmaceutical-, food-, semiconductor-, and aerospace production facilities, have similar hygienic requirements. Ventilation and air conditioning systems in these buildings need to comply with official hygiene requirements ensuring that no dangerous, hazardous, or risky substances are released to the surrounding environment.

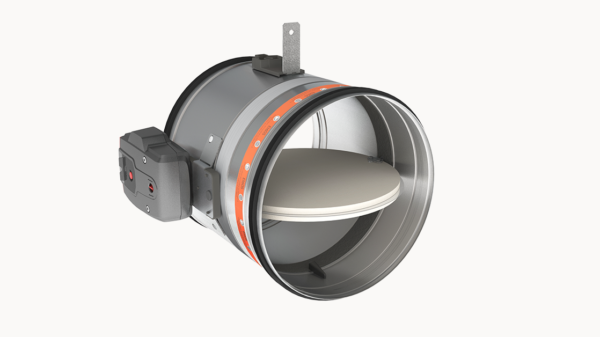

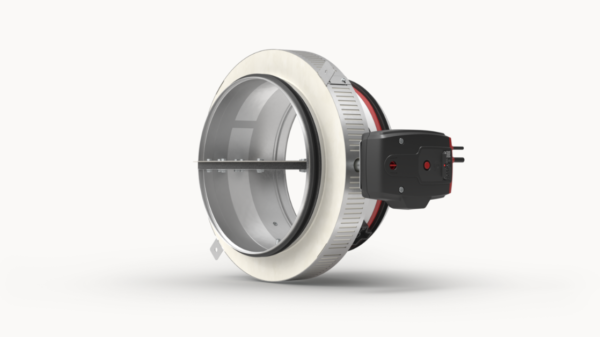

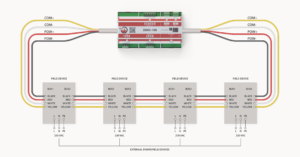

Installed in these ventilation systems, our fire dampers have to meet the same demanding requirements of hygiene and safety. Our CU2, CU-LT, CR60 and CR120 (rectangular and round) fire dampers carrying a Hygiene Tested label, meet these critical air cleanliness and very critical hygiene requirements. The manufacturing process, materials, constructional and operational design, do not affect Health by any meaning.

Hygiene standards and certifications

Our Hygiene Tested fire dampers comply with the official hygiene requirements specified by the applicable standards and regulations relating to ventilation and air conditioning.

The most established hygienic air handling unit certifications globally and alternative for the multitude of different guidelines is the Eurovent Certified Performance for Hygienic Air Handling Units. This certification is generally appreciated, and a common reference for engineers, planners and installers. For some countries there are (additional) local hygienic guideline. For Germany*, for instance, the VDI 6022-1 for general ventilation and lower healthcare applications or the DIN 1946-4 codes. For the UK this is HTM 03-01 standard. For Poland PZH Atest Higieniczny, and for Switzerland SWKI VA 104-01 (similar to VDI).

Other relevant standards and norms are:

- EN 779 Particulate air filters for general ventilation (filtration efficiency)

- EN 1822 (all parts) Particulate filters (HEPA and ULPA)

- EN 13779 Ventilation for non-residential buildings – Performance requirements for ventilation and room-conditioning systems

- ISO 14644-3 Clean rooms and related clean room areas – test methods

- DIN 1946-4 Ventilation and air conditioning in health care

- SWKI Guideline 99-3 Heating and air conditioning systems in hospital buildings

- ANSI/ASHRAE Standard 170 Ventilation of health care facilities

- European standard

EN 13779 (09/2007) Air Handling – Performance requirements for ventilation and room-conditioning systems - Austrian standards

ÖNORM H 6021 (09/2003) – ÖNORM H 6020 (02/2007)

(*) VDI stands for ‘Verein Deutscher Ingenieure’ (Association of German Engineers). They have devised several guidelines that have become a standard for engineering today. VDI itself is not a certification body. VDI 6022 aims to create healthy air in buildings and deals with the hygiene of ventilation and air conditioning systems and devices with the minimum goal of ensuring that the air released into the room is no worse than the air drawn in by the device or system.

VDI 6022-1, a subdocument of VDI 6022, puts specific focus on ventilation and indoor air quality. It defines hygiene requirements for ventilation and air-conditioning systems and units. VDI 6022-1 is a code of practice according to which accredited third-party certification bodies or individual auditors can perform audits. To maintain the certificate, VDI certified products need to undergo regular audits.